Why is health and safety a crucial element in anaerobic digestion plants?

At Eco Verde Energy (EVE), we believe that health and safety should be at the heart of how we run our anaerobic digestion (AD) plants. As health, safety, environment, and quality (HSEQ) director Will Rogers explains health and safety is integral to our remit of operational excellence and plant optimisation.

The importance of health and safety in the AD industry

Legally, operators are bound by numerous regulations, including the Health and Safety at Work etc Act 1974, however, beyond these legal obligations, putting employee health and safety at the heart of operations is key to the company’s success says HSEQ director Will Rogers.

Mr Rogers explains, “Health and safety is essential for plant optimisation. To enable safety and health, a clear system of management needs to be defined, and relevant to all parts of the business, to deliver all the essential requirements for safe operation of an AD plant.”

“For example, by conducting risk assessments, using a collaborative approach, you can identify opportunities to improve processes and ensure efficiency and safety, this is all part of EVE’s continuous improvement approach.”

By ensuring efficient production, AD sites can maintain consistent outputs, producing reliable supplies of biomethane to replace fossil fuels and reduce emissions.

What is AD plant optimisation?

“A well-optimised plant achieves the best overall performance and output through efficient, reliable operations supported by a strong focus on health and safety management,” says Mr Rogers.

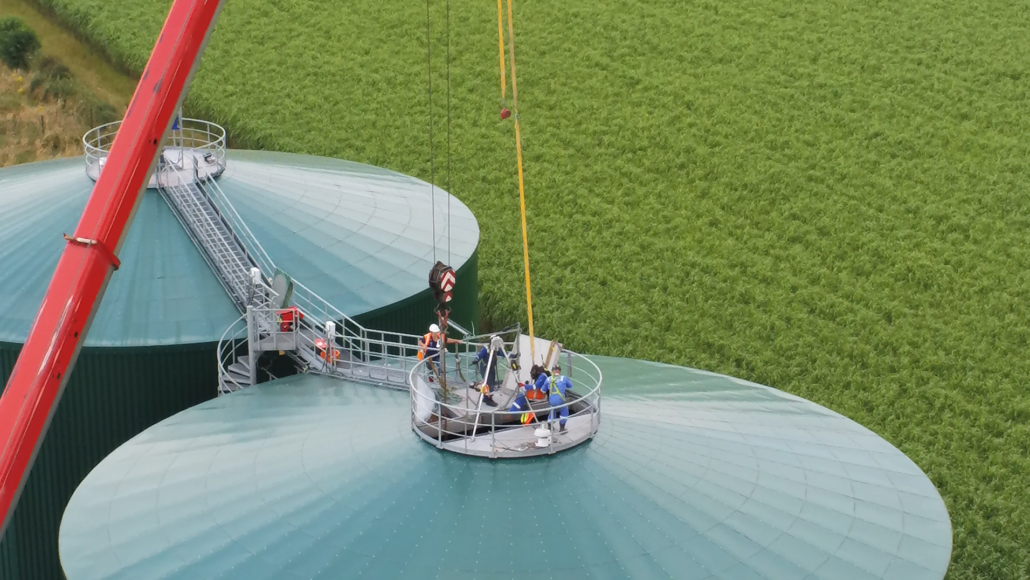

By identifying risks to people and equipment, and implementing measures to mitigate these risks, plants can ensure that operations run smoothly and efficiently.

“For instance, when we introduce new equipment or processes, we conduct a thorough risk assessment, through our ‘management of change’ process to identify any potential problems before they occur so that we can proactively work to solve them,” says Mr Rogers.

“I believe our company wide lone worker and gas detection systems, simplified QR code-based incident reporting process, robust safe systems of work, and employee engagement approach are the best in the industry. Our primary aim is to protect our staff and those around us from potential dangers, fostering a positive workplace culture and allowing people to thrive in the working environment. All the while working constantly to improve our efficiency and enabling improvement from the ground up,” he adds.

The journey towards excellence in AD plant

In November 2023, our commitment to using occupational health and safety systems to protect against work-related injuries and illnesses was recognised when we achieved ISO 45001 certification.

“Internally, we know our quality, environmental and occupational health and safety standards are high, but having third-party validation that we’ve met a high international standard is a huge confidence boost,” says Mr Rogers.

“We understand that the optimisation of AD plants goes hand in hand with rigorous health and safety practices. By integrating these practices into our daily operations, we not only comply with legal requirements but also create a safer, more efficient and sustainable environment.

“This commitment to health and safety is a key factor in our ability to provide reliable, green energy solutions to our community,” he says.

A “community-centric” approach

A safe environment is particularly important for attracting talent and building a reputation as a responsible local employer. Safe operating environments are essential for hands-on roles such as waste handling, engineering or delivery drivers who transport waste to the plant, all key roles which keep the AD process flowing. EVE are keen to ensure safe operations so that the impact on local communities is only a positive one.

“With the renewables sector workforce set to grow by up to 46%, it’s important that we work hard to find the best people to help us on our journey to reduce the UK’s emissions,” Mr Rogers concludes.