A career spotlight into anaerobic digestion site management

At Eco Verde Energy (EVE), we’re not just about creating renewable energy solutions; we’re about developing the talents and skills of the people who drive our success.

In this blog, we dive into the experiences and insights of Tyler Warman, the dynamic Site Manager at our Ellough anaerobic digestion (AD) plant in Beccles, Suffolk.

Shortlisted for the BREA awards in 2022, Tyler’s journey from one-time scaffolder to leading a critical green energy facility offers a unique insight into routes to the AD sector.

What does an AD site manager do?

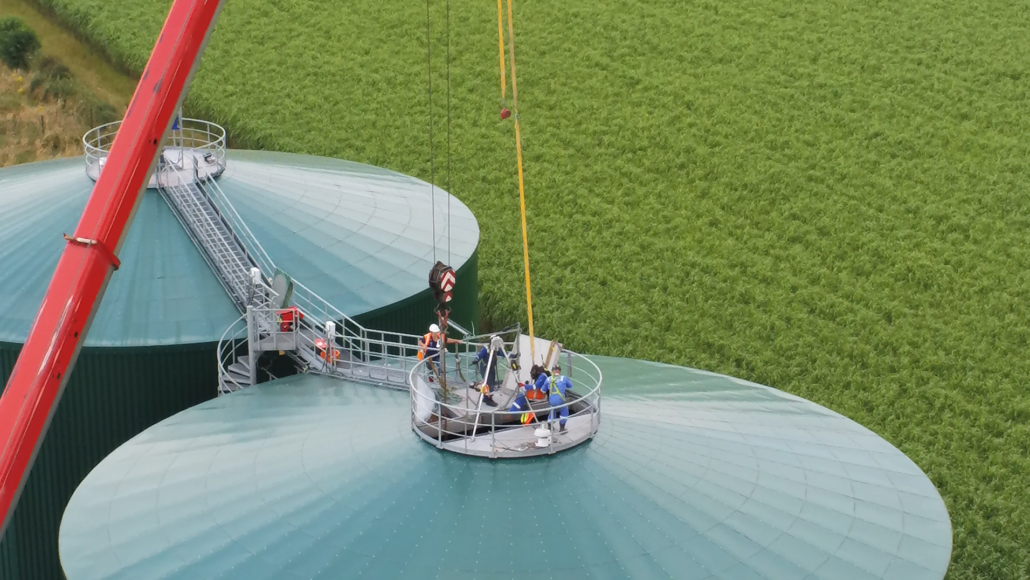

Tyler describes his role as the site manager of a 12-megawatt anaerobic digestion facility.

Responsible for the daily operation and output of the Ellough AD plant, his work involves transforming feedstocks, like maize and sugar beet, into biogas, which is refined into biomethane and fed into the national grid.

Ellough is the largest gas-to-grid AD facility in the East of England, converting 100,000 tonnes of energy crops into sustainable gas, powering up to 9,000 local homes and businesses each year.

The plant also supports local farmers to become more sustainable with the production of digestate, an eco-friendly alternative to synthetic, carbon intensive fertilisers.

Tyler emphasises the meticulous planning, preventive maintenance, and the importance of health and safety in his daily responsibilities.

As the site manager, Tyler’s daily responsibilities can include:

- Consulting with operators and contractors to plan daily issues and projects

- Reactive planning, supervising checks and maintenance

- Optimising the flow of feedstocks and ordering parts to ensure site performance

- Enhancing operational output and planning the maintenance schedule to avoid downtime

- Managing staff, training and development

- Conducting site inspections to ensure proper operations

- Assisting operators with maintenance tasks

- Balancing administrative duties with hands-on site work

Read Tyler’s blog on five things to consider when maintaining an AD plant.

Journey into AD

Tyler’s foray into anaerobic digestion (AD) started through spotting an ad at a recruitment agency, while looking for operations and maintenance engineer roles.

His career journey began with a stint in the service industry at McDonald’s while studying electrical engineering in college. While searching for an apprenticeship, he worked as a scaffolder and his determination led to a successful four-year apprenticeship in electromechanical engineering.

During this apprenticeship, Tyler learned a variety of skills including service repairs and installations for many different industries, including oil and gas, water, and food manufacturing.

His first role in AD began in 2019 as a Site Operator at Ellough. When EVE took ownership of the site in 2020, Tyler quickly progressed his career and was soon promoted to his current role as Site Manager.

He believes this diverse background has enriched his skills, making him adaptable with the interpersonal and hands-on skills needed for managing a team and suppliers. This enables him to switch from the demands of back-office to on-site work. Tyler enjoys this variety and pace, and it is part of what appeals about his role as a site manager.

Tyler says there is no typical entry route to the sector among his team and notes that most of his new recruits come from transferable engineering, maintenance or operational backgrounds with experience in mobile plant engineering or factory work.

He notes that hands-on mechanical experience, such as handling motors, gearboxes or pumps, stands recruits in good stead for operational roles.

Leadership and Management

As the youngest Site Manager at EVE, moving into management was a significant shift for Tyler.

Since starting his Site Manager role, Tyler has implemented new systems and improved the site’s energy output by 20%.

He values a hands-on approach and believes in supporting his team both on the ground and administratively. He attributes the site’s success to having a well-rounded, hardworking and pro-active team.

Tyler’s strategic thinking has also led to improvements in site safety and environmental performance, while delivering cost savings. His efforts in rolling out new health and safety training underscore his critical role in advancing the team’s skills.

This inclusive leadership style has created a collaborative, efficient working environment at Ellough.

Addressing the AD awareness gap

Prior to joining the industry, Tyler’s knowledge of the AD sector was scarce. He is quick to mention that AD wasn’t a well-known career path in schools, indicating an awareness gap about this vital industry. Among friends and family, Tyler notes that his job is understood as ‘working at a renewable gas plant’.

Looking to the future, he believes it is vital for the sector to address this lack of awareness to promote the benefits of AD for meeting the UK’s climate goals and for attracting new talent to the sector as we transition from fossil fuels.

Want to learn more about the AD process? Watch our anaerobic digestion animation video

Myths and misconceptions in AD

Tyler addresses common misconceptions about AD, noting that despite logistical challenges of transporting feedstocks, it is a sustainable process.

Concerns from those outside the sector often centre on farmland being used for energy crops and diesel emissions from tractors. At sites like Ellough, every aspect, from diesel usage to farm distance, is meticulously calculated to ensure the process meets Ofgem’s sustainability criteria.

Notable achievements

In 2022, Tyler was highly commended for the Young Renewable Energy Professional Award at the British Renewable Energy Awards, recognising the impact of his early career achievements and leadership potential.

Tyler is passionate about recruiting others into the renewables sector. He says his proudest achievement is bringing in new members of staff with no prior experience of AD and developing a competent team capable of maintaining high operational and safety standards across all aspects of the site.

As a leader, Tyler notes he would not ask his team to do anything he is unwilling to do himself and believes in the importance of having an open dialogue. It is important, he says, for them to feel confident in approaching him if they need support or guidance on how to carry out certain tasks.

Impact on Climate Goals

Tyler’s work contributes significantly to net zero goals, with Ellough supplying green gas to local homes and businesses, displacing the need for natural gas and cutting greenhouse gas emissions.

This is something he is proud of, and he stresses the importance of AD in tackling unavoidable food waste, building the UK’s energy resilience and in assisting sustainable farming practices.

Advice for Aspiring AD Professionals

For those eyeing a career in AD or renewables, Tyler’s advice is to explore various roles across different industries.

This exposure provides a broader understanding of the valuable transferrable skills needed to succeed in AD such as interactions with colleagues and contractors, understanding process control, implementation, and delivery.

Linking back to his earlier point on education, Tyler also emphasises the need for greater investment in industry-specific training and qualifications to streamline pathways into AD careers.

While the industry presents its challenges, Tyler believes that the diversity of work, problem-solving, and daily learning opportunities in AD offer immense job satisfaction.

Tyler’s journey and insights paint a vivid picture of the opportunities and variety in the AD sector. His commitment to innovation, team development, and sustainability embodies the ethos of Eco Verde Energy. As we continue to champion green energy solutions, it’s the dedication and expertise of individuals like Tyler that drive us forward.

Be part of the renewable future with EVE

Eco Verde Energy (EVE) has a clear vision of being the best AD and green energy services provider, shaping a sustainable, carbon-neutral world.

We’re more than just an AD service provider; we’re educators, advisors and passionate advocates leading the drive for a circular economy.

EVE is always looking for talented people to join our team.

From consultative roles to hands-on operational tasks, the opportunities are vast and varied. All we ask is that you have an interest in renewables and a drive to help our team decarbonise the UK’s energy network.

To see our latest vacancies, please visit ecoverde.energy/careers or contact hr@ecoverde.energy

Anaerobic Digestion (AD) could save over 200,000 tonnes of food waste from landfill

Leading green energy services provider, Eco Verde Energy (EVE), has announced it now has the capacity to divert 201,000 tonnes of unavoidable food waste from landfill into anaerobic digestion (AD), creating enough renewable heat and power to supply nearly 38,500 homes in the UK.

By processing this waste within four of the plants under the company’s management, EVE could save 108,000 tonnes of CO2 emissions every year, which is the equivalent of 250 million road miles[1].

Speaking about the milestone, Dean Bullen, Managing Director for EVE says: “We can all do more to reduce our impact on the environment.

“Whether that be through reducing the amount of food we actually waste or being more conscious about where our unavoidable food waste goes.”

According to WRAP, the UK creates 9.52 million tonnes of food waste per year. Despite measures to reduce this waste, there remains some types of food that cannot be eaten or used in any other way, often referred to as ‘unavoidable’ food waste.

This waste can serve a useful purpose at an AD plant, of which there are 740[2] in the UK.

“From 2026, all local authorities will need to introduce separate kerbside food waste collections, so having a sustainable means of processing this waste will become even more important,” says Mrs Marshgreen.

“We’re very proud to play our part in reducing the UK’s emissions and turning something that would otherwise rot away in landfill, into renewable gas that can be used to heat homes and power appliances.”

Click here to read more: https://ecoverde.energy/news/anaerobic-digestion-could-save-over-200000-tonnes-of-food-waste-from-landfill/

[1] What does a tonne of CO2 look like? (edenseven.co.uk)

[2] ADBA Policy & Market Report | April 2024

This week, we held our IOSH Managing Safely course!

The course was delivered by our lead trainer, Christine Mapp, who trained both our internal EVE colleagues and external participants.

We are thrilled to announce that all members who sat the exam and project passed with high scores. Feedback and engagement from delegates were extremely positive;

“Christine has a wealth of knowledge and is extremely helpful and motivating throughout the course”

“The trainer’s knowledge and enthusiasm was brilliant in keeping the class engaged”

EVE is certified to deliver IOSH Managing Safely courses. We can offer this widely recognised and respected training at our head office in Cambridgeshire or your premises for groups of 8 or more. EVE can deliver this course for individuals or companies.

To find out more about the training we offer, click here, or drop us a message.

#IOSH #IOSHTraining #EVE #Health&SafetyTraining #SafetyFirst

We have been shortlisted for three awards!

We are thrilled to announce that the Eco Verde Energy (EVE) team has been shortlisted for three awards at the AD and Biogas Industry Awards 2024. The three awards we have been shortlisted for are:

The AD and Biogas Industry Awards, organised by ADBA and WBA, recognise and celebrate achievements across the full spectrum of the anaerobic digestion (AD) and biogas industry. The Awards Ceremony will take place during the week of the World Biogas Expo in July.

A huge congratulations to everyone who has been shortlisted. We look forward to the awards ceremony and to celebrate the remarkable achievements of all the finalists.

Why is health and safety a crucial element in anaerobic digestion plants?

At Eco Verde Energy (EVE), we believe that health and safety should be at the heart of how we run our anaerobic digestion (AD) plants. As health, safety, environment, and quality (HSEQ) director Will Rogers explains health and safety is integral to our remit of operational excellence and plant optimisation.

The importance of health and safety in the AD industry

Legally, operators are bound by numerous regulations, including the Health and Safety at Work etc Act 1974, however, beyond these legal obligations, putting employee health and safety at the heart of operations is key to the company’s success says HSEQ director Will Rogers.

Mr Rogers explains, “Health and safety is essential for plant optimisation. To enable safety and health, a clear system of management needs to be defined, and relevant to all parts of the business, to deliver all the essential requirements for safe operation of an AD plant.”

“For example, by conducting risk assessments, using a collaborative approach, you can identify opportunities to improve processes and ensure efficiency and safety, this is all part of EVE’s continuous improvement approach.”

By ensuring efficient production, AD sites can maintain consistent outputs, producing reliable supplies of biomethane to replace fossil fuels and reduce emissions.

What is AD plant optimisation?

“A well-optimised plant achieves the best overall performance and output through efficient, reliable operations supported by a strong focus on health and safety management,” says Mr Rogers.

By identifying risks to people and equipment, and implementing measures to mitigate these risks, plants can ensure that operations run smoothly and efficiently.

“For instance, when we introduce new equipment or processes, we conduct a thorough risk assessment, through our ‘management of change’ process to identify any potential problems before they occur so that we can proactively work to solve them,” says Mr Rogers.

“I believe our company wide lone worker and gas detection systems, simplified QR code-based incident reporting process, robust safe systems of work, and employee engagement approach are the best in the industry. Our primary aim is to protect our staff and those around us from potential dangers, fostering a positive workplace culture and allowing people to thrive in the working environment. All the while working constantly to improve our efficiency and enabling improvement from the ground up,” he adds.

The journey towards excellence in AD plant

In November 2023, our commitment to using occupational health and safety systems to protect against work-related injuries and illnesses was recognised when we achieved ISO 45001 certification.

“Internally, we know our quality, environmental and occupational health and safety standards are high, but having third-party validation that we’ve met a high international standard is a huge confidence boost,” says Mr Rogers.

“We understand that the optimisation of AD plants goes hand in hand with rigorous health and safety practices. By integrating these practices into our daily operations, we not only comply with legal requirements but also create a safer, more efficient and sustainable environment.

“This commitment to health and safety is a key factor in our ability to provide reliable, green energy solutions to our community,” he says.

A “community-centric” approach

A safe environment is particularly important for attracting talent and building a reputation as a responsible local employer. Safe operating environments are essential for hands-on roles such as waste handling, engineering or delivery drivers who transport waste to the plant, all key roles which keep the AD process flowing. EVE are keen to ensure safe operations so that the impact on local communities is only a positive one.

“With the renewables sector workforce set to grow by up to 46%, it’s important that we work hard to find the best people to help us on our journey to reduce the UK’s emissions,” Mr Rogers concludes.

Click here for current vacancies.